From Virtual to Reality

/

Improving Cios Solo

Through VR

Project: Cios Solo

Brand: Siemens Healthineers

Year: 2020

#VBL #DesignStrategy #Validation #VirtualReality #MedicalDevice

Following the successful development of a new Visual Brand Language (VBL) for their ultrasound machines, Siemens Healthineers is now extending this design system to their C-arm product line. To achieve this, they have partnered with designaffairs, bringing together expertise from both their German and Shanghai teams.

This collaboration aims to create a cohesive, future-forward design language that enhances usability, aesthetics, and brand recognition in the medical imaging space.

We embarked on a deep dive into the world of medical imaging, visiting Siemens Healthineers' design and development center in Shanghai. There, we worked closely with engineers to uncover the intricate details of the C-arm system—how it's built, assembled, and fine-tuned for precision.

But beyond the mechanics, we sought to understand the human experience. By consulting experts and understanding real-life workflows, ensuring that our design would not only be aesthetically appealing but also truly intuitive and supportive in critical medical moments.

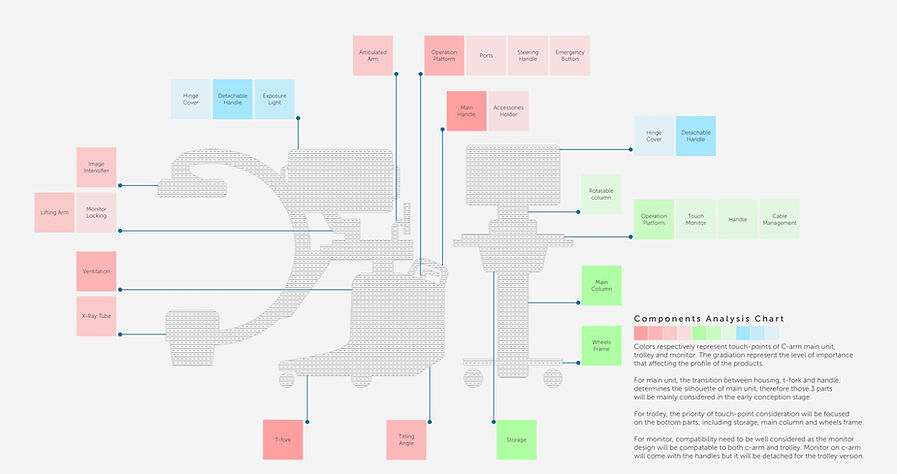

C-arm system is highly complex, composed of multiple interconnected components. Some of these elements have a more significant impact on the overall appearance than others. To navigate this complexity, our team developed the priority chart shown below. This chart helped us analyze and visualize the hierarchy of components, ranking them from those with the greatest visual and functional influence to those with the least. This structured approach guided our next steps in the ideation process, ensuring that our design exploration focused on the most impactful areas first.

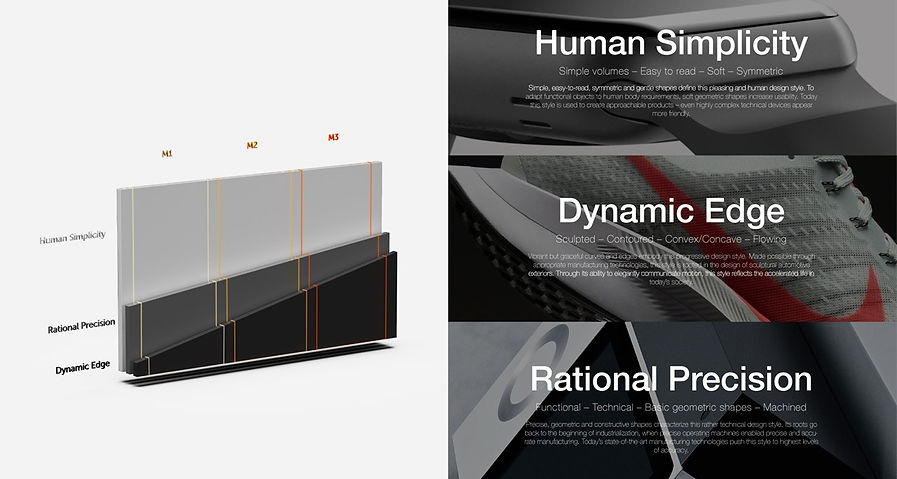

At the same time, we engaged with the Siemens Healthineers design team to gain a deeper understanding of the newly defined Visual Brand Language (VBL). They shared insights into the emotions and values the brand aims to convey, as well as key learnings from their initial application of the system on the ultrasound machine. By building on their experiences, we ensured that our design approach for the C-arm would not only align with the brand vision but also refine and elevate the VBL for future applications.

We also redesigned the barrel, exploring ways to make it more compact and lightweight for extended use without causing fatigue. Additionally, we refined the button placement for easier control and shaped the overall form factor to be smooth and ergonomic, ensuring a comfortable grip.

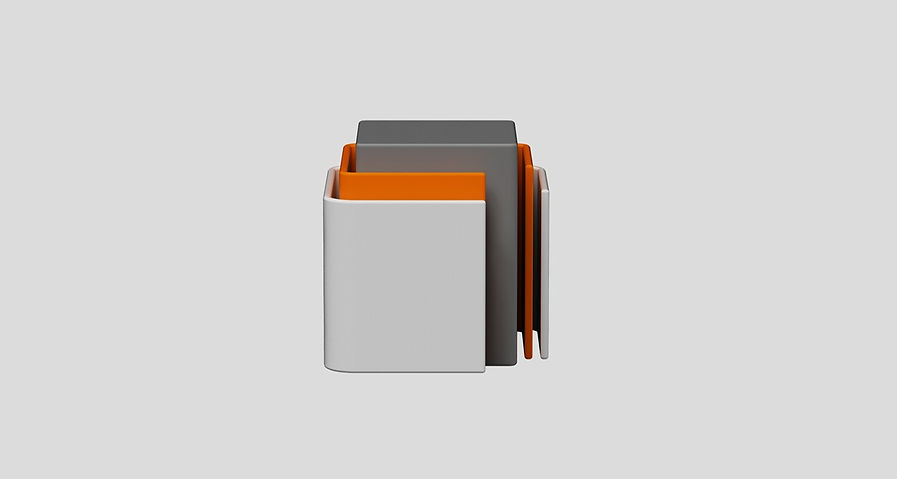

One of the most defining signatures of the design language is the "Layering" story. The product is intentionally divided into distinct layers, each carrying its own design attributes and conveying a specific message. This approach not only enhances the visual clarity of the C-arm system but also reinforces the brand's identity by structuring the design into meaningful, purpose-driven segments.

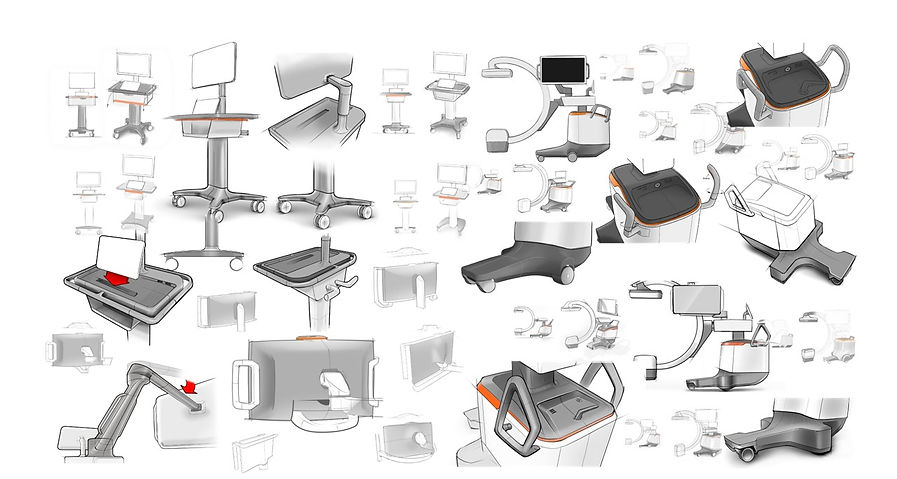

Our designaffairs Shanghai team collaborated closely with the German design team in a co-creation ideation process, exploring how the Visual Brand Language (VBL) system could evolve and extend onto the C-arm. Through this cross-border partnership, we aimed to refine and adapt the design principles to seamlessly integrate with the complexity of the C-arm system while maintaining the essence of Siemens Healthineers’ brand identity.

One of the biggest challenges in validating our ideas was the sheer scale of the C-arm—building physical prototypes for every iteration would have been extremely costly. To overcome this, our team leveraged Oculus VR headsets and KeyVR (KeyShot’s VR tool) to review our 3D concepts in a true-to-scale virtual environment. This allowed us to experience the design in real-world scenarios, refine details efficiently, and make confident decisions before moving to physical prototyping.

In a previous project, we designed a logistics delivery robot, we also used KeyVR and animation tools to explore various shelf and door concepts. By simulating the loading and unloading experience in a true-to-scale virtual environment, we were able to test and refine the interaction flow and user experience before finalizing the design. This approach allowed us to identify potential issues early and ensure the most efficient and intuitive experience for handling packages.

Throughout the VR validation process, we were able to review and refine details within a true-to-scale environment. This approach allowed us to carefully assess the user experience of both the C-arm and trolley in real-world medical scenarios, ensuring seamless interaction, intuitive operation, and ergonomic efficiency.